[quote=Champ;259099]Hi Axel31 found this might help

Kind Regards

Champ

Tramsvalps bloggis

Countershaft wear - fix and prevent

Worn countershaft splines is a known problem on the Transalp.

Tramsvalps bloggis

Countershaft wear - fix and prevent

Worn countershaft splines is a known problem on the Transalp.

Changing the shaft means dismantling the whole engine.

Prevent this with my simple fix:

I have been driving 10.000 km with my latest sprocket "glued" to the shaft with high strength threadlocker, so I know this works on my shaft, and that it lasts the lifetime of the sprocket.

No more wear on my splines.

You of course do this at your own risk.

All you need is:

•

Permatex® High Strength Threadlocker RED or Loctite etc equivalent

• Some cleaner

• Wire

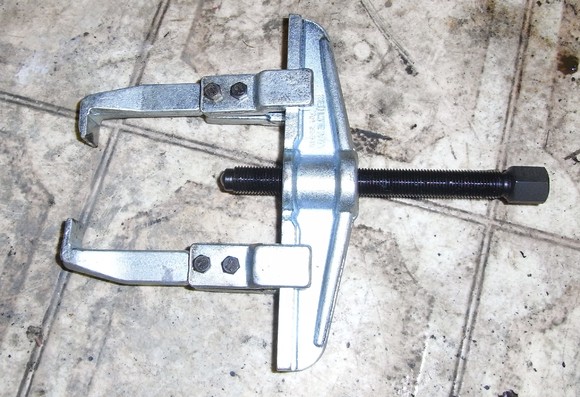

• A cheap puller

This one component threadlocker is runny enough to trickle into the splines (with a little help),

it gets very hard after curing, and is very easy to scrape off the splines when changing sprockets.

Read the

instructions pdf.

This is the only one I've tried, there may be others better suited for more badly worn shafts.

The threadlocker between sprocket and shaft is intact after 10.000 km.

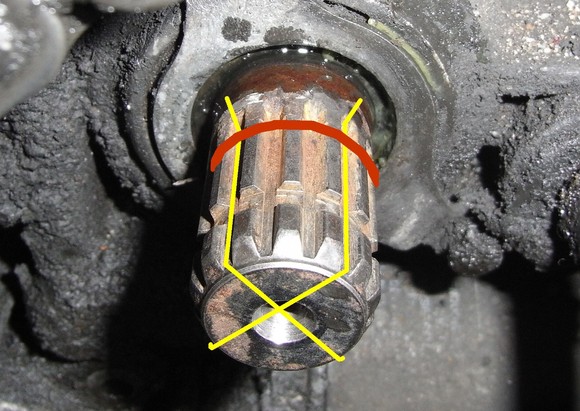

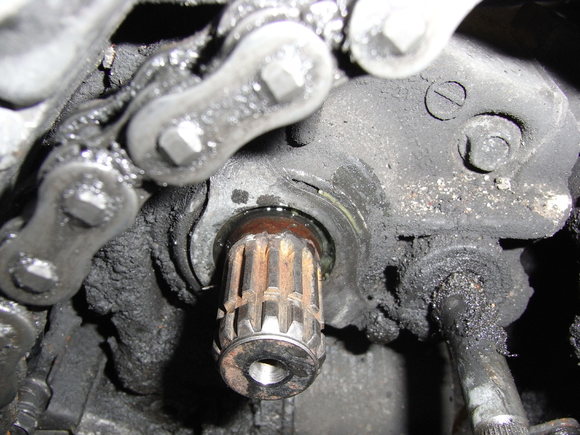

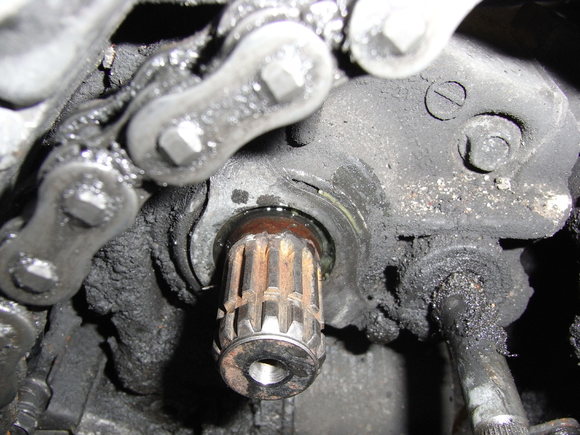

My shaft (TA650 2002, 75.000 km), you can see the splines are worn where the sprocket sits.

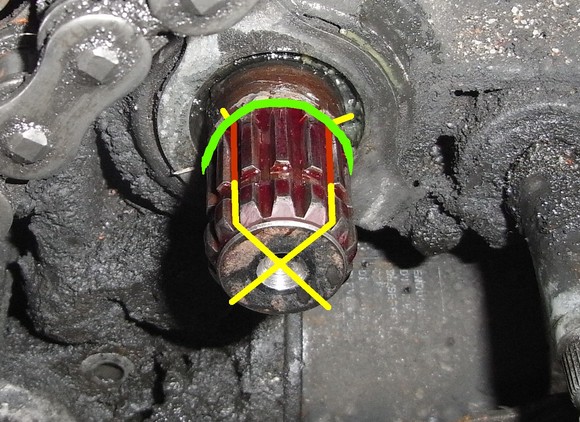

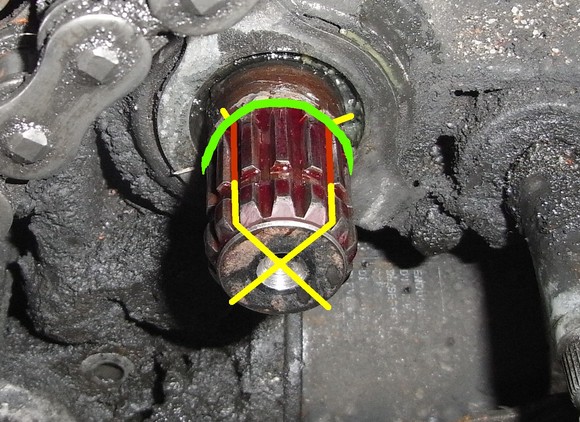

To centre the sprocket, use thin wire on the bottom of the shaft splines.

Something like this, with a rubber band to hold it in place.

A fresh and tight fitting shaft/sprocket may need no centering at all (guessing).

If you're going to keep the chain, just lift it off the rear sprocket if possible.

Tie the chain up so the front sprocket is free. The chain must

not touch the sprocket while the threadlocker cures.

Clean the shaft and sprocket. If you use a wire brush, be careful with the shaft's rubber seal.

Find a suitable wire diameter. A tight fit is vital, both for centering and later removal.

(I use 0,3 mm with a JT sprocket.)

Lean the bike a bit to the

right so the threadlocker fluid will be able to trickle into the splines.

Put a little oil on the shaft next to the engine to prevent excess theadlocker fluid from sticking there and maybe ruin the seal.

Smear threadlocker fluid on the shaft, wires and sprocket. You now have about 10 minutes before it cures, depending on temperature.

Put the sprocket in place, and add more fluid as you turn and slide the sprocket back and forth to fill the splines completely (with the bike leaning to the right).

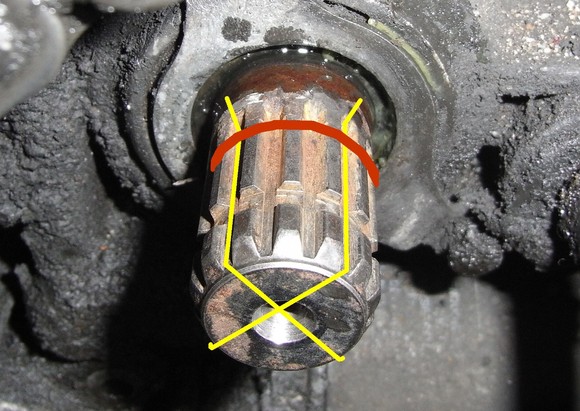

Lastly, slide the sprocket slightly past the groove to get its splines in line with the undamaged shaft splines. Then gently slide it back in, edge to edge with the shaft groove.

If the sprocket is not centered, or if its splines are not in line with the undamaged shaft splines, the sprocket may be difficult to remove.

Difficult = You may have to heat it to 230°C (450°F) and pull while hot, or, lacking heat, cut it up with an angle grinder...

But if well centered and in line, just pull cold, no problems.

Keep a good curing temperature, and wait for 24 hours (read pdf instructions).

Time to check the result - just start the engine and watch (no gear needed).

If you're satisfied - cut off the wires, put the locking plate in place and go for a ride.

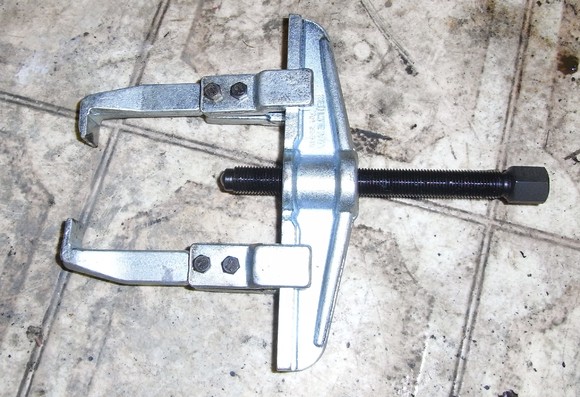

My old glued sprocket was steady as a rock after 10.000 km, but I had no problems removing it with a cheap puller.

The locking plate was stuck between sprocket and groove and needed a little knocking to turn, since my sprocket had moved a little outwards. But no problem. If this happens to you, do

not try to force the sprocket inwards, as this may ruin the bearings.

This also applies if the sprocket doesn't come off:

Do not try to force the sprocket back in!

Warning:

Warning: Do not use strong threadlocker on

screws you want to be able to remove.

Good luck! Feedback appreciated.

/Tramsvalp

Skrivet av

Tramsvalp, 2009-01-13 03:18

Tried this on an XR600, worked for a while, but after 1000 km the sprocket came loose again.

I did cheat however and didnt use any wire, only manually centering and plenty of the red loctite, dont know if wires would have made any difference though. I guess XR600 applies higher stress on the shaft than the Transalp?

Skrivet av XRUlf, 2009-07-23 18:45

To XRUlf:

I don't know if red Loctite is the same as red Permatex. Did you cheat in any other way, with cleaning or curing time maybe? It's vital to get rid of all air pockets in the joint, the threadlocker should have nowhere to go.

The wires add no strength, but provide an even gap between the parts. A bigger gap at one end takes longer to cure.

Skrivet av

Tramsvalp, 2009-07-29 01:59

Kommentera:

Signatur:

Skriv

här:

-------------------------------------------------------------------

Nice one Champ - I think I saw this on ADV.

I have arranged a very simple manual oilfeed (EP-80 gearbox oil)which drips onto the splines. It could be fed automatically with a chainoiler, but I havent done that yet.

But your method works well, so no need for the oiler. I will try your method at a later date.

här:

här:

Linear Mode

Linear Mode